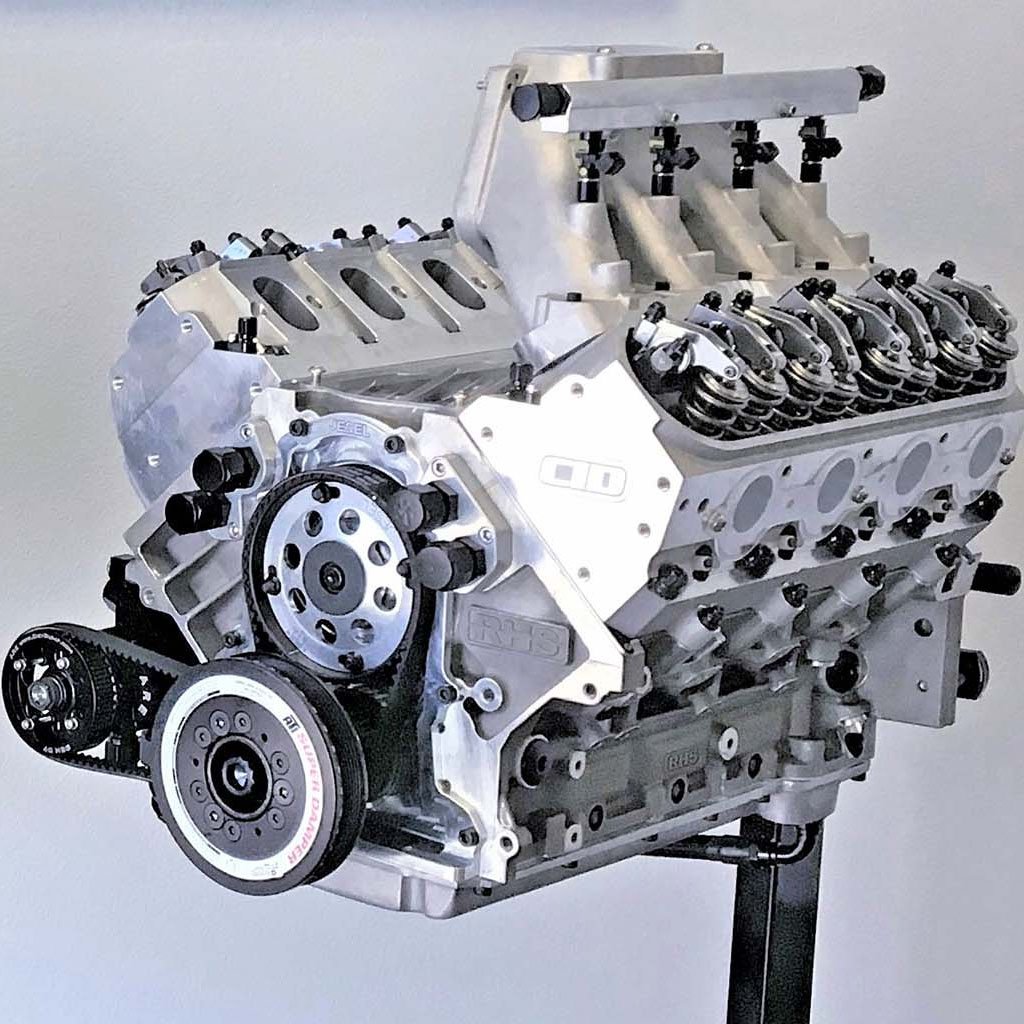

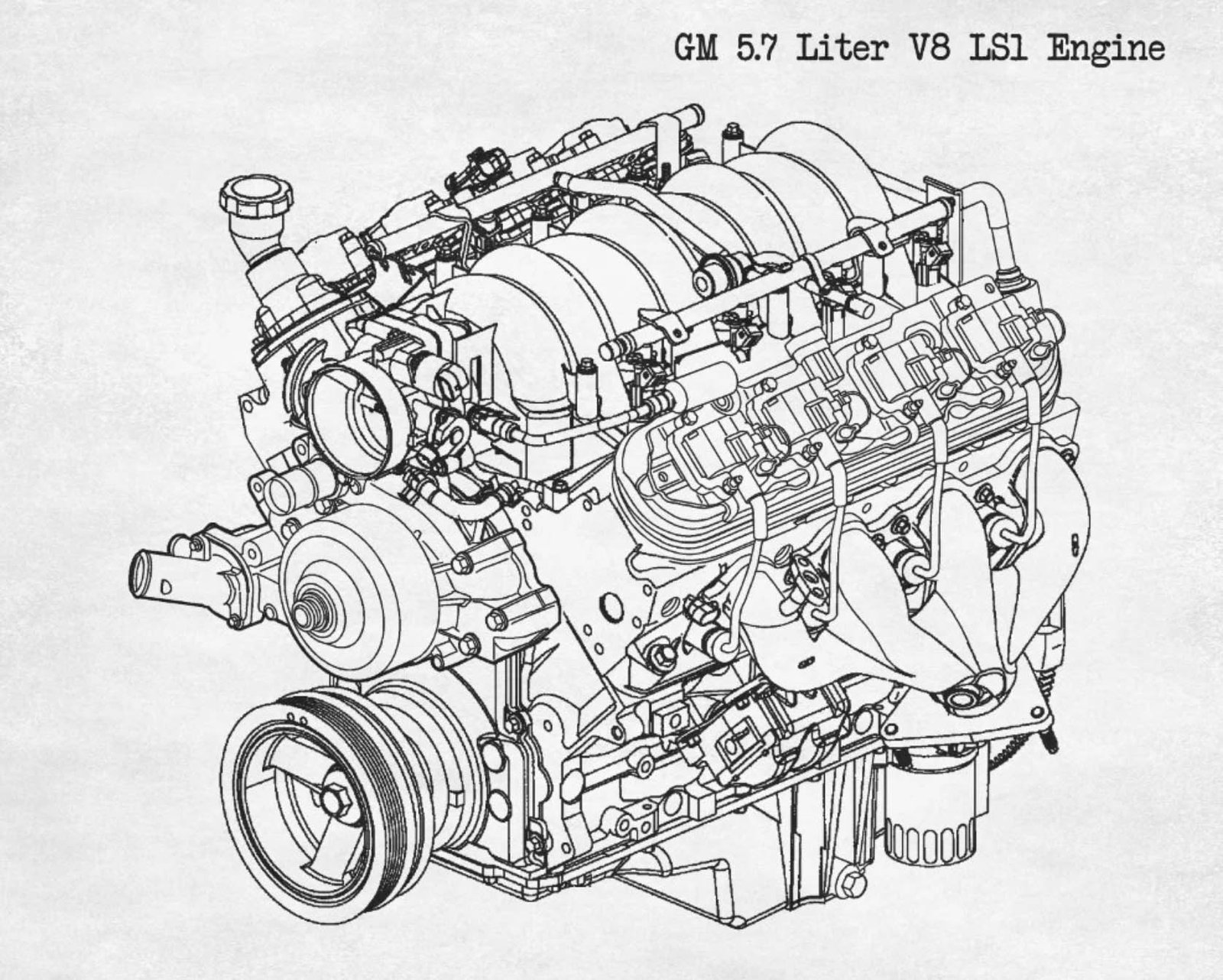

LS1: The Engine That Changed it All The LS1 (5.7 liter, 346ci) was the engine…

The Definitive Guide to LS, LSX, and Vortec Engines: History, Specifications, and Swap Essentials – Part2

Differences in LS Heads

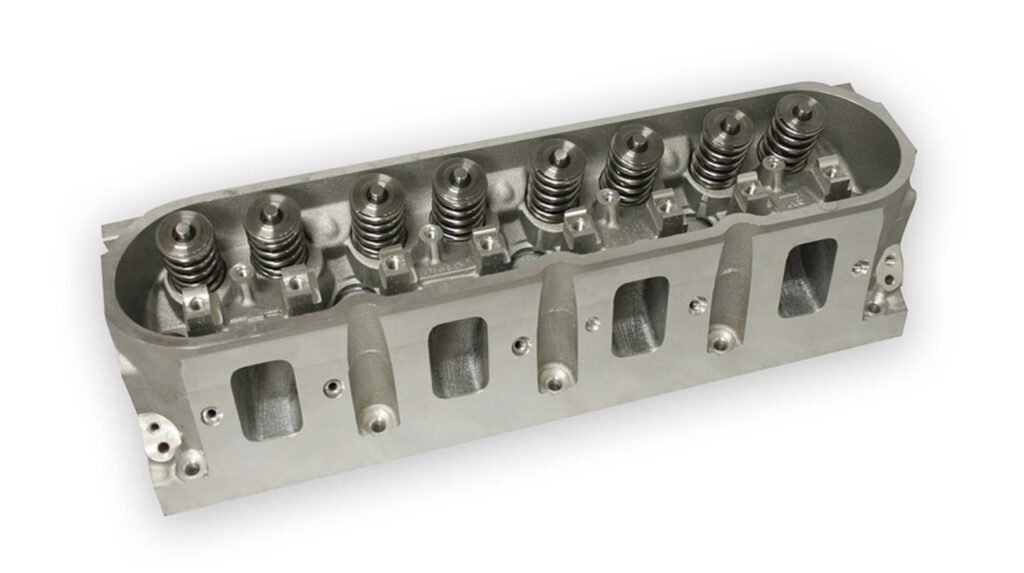

Like the blocks, the cylinder heads used on the various LS engines continued to evolve over the course of the program. Technically you can bolt any LS head to any LS engine, but due to varying bore and valve sizes you could run into valve-to-block clearance issues. So, a good rule of thumb is that LS1 and LS6 engines can only run LS1, LS6, and LS2 cathedral port heads (and their truck equivalents). LS2 engines, due to the larger 4.00-inch bore design, can run LS1, LS6, and LS2 cathedral port heads in addition to the newer rectangular port LS3/L92 heads. The LS3 engines (or any of the 6.2-liter-based variants like the L92, LSA, etc.) can run any head except the LS7 rectangular-port heads. LS7 engines can run any LS-series head, but running the smaller heads would be nonsensical from a performance standpoint. So, for best results make sure to match the cylinder to the bore size you’re working with.

Nearly all LS engines utilize the same cylinder head bolt pattern, which is why the heads are so easily swapped around. Most have four 11mm bolts per cylinder (for a total of 10) along with an upper row of five 8mm bolts. The LS1 engines (including the LS6) had bolts of different lengths (in regards to the 11mm fasteners), but from 2004 forward all went to the same length. To better withstand boost, LS9 engines received 12mm bolts. Also, keep in mind that each head variant requires a compatible intake manifold, so an LS3 intake won’t fit an LS7, and so forth. Of course there’s a nearly endless array of aftermarket heads to choose from, some of which are hybrids (cathedral ports but with large LS3 sized intake valves, LS3 port but with LS7 rockers, etc. ). Below are the four main factory cylinder heads you’ll encounter.

LS Cathedral Port Heads

Debuting on the LS1 the cathedral port heads were named for the distinctive shape of their intake port. Any intake manifold (LS1, LS6, LS2) will work with these heads as well as Vortec intakes from cathedral port-headed variants. 241 castings (the casting number is found near the corner of the head) are the most common since they were used on every 4.8L and 5.3L truck engine as well as the early LS1s. The LS1 heads have 67cc chambers with 2.00/1.55-inch valves.

Other heads you’ll run into are 852 or 706 castings which have smaller 61cc chambers and 1.89/1.55-inch valves. These are best for high-compression builds and really need larger valves and porting work. 799 heads (65cc chamber and 210cc intake runner) are pretty much 241 LS6 heads worked over for truck engines and thus are a real treasure to find when hunting through boneyards. Aside from the casting number, they have distinctive D-shaped exhaust ports. 243 castings are harder to come across and are sometimes called LS2 heads. On the truck side, these would be 035 or 317 castings (LQ9/LQ4) and featured 71cc chambers. You may even find 873 castings from the early LQ4 engines, but they are iron and not worth bothering with. Also, the early perimeter-bolt heads (933 and 806) are far less desirable. Remember, not all 243 heads are LS6 heads, but all LS6 heads are 243 castings. True LS6 heads will have the stainless steel hollow-stem valves.

- 933—1997 models, aluminum, perimeter-bolt valve covers, 5.7 liters

- 806—’97-’98, aluminum, perimeter-bolt, 5.7

- 853—’99-’00 (LS1), aluminum, center-bolt, 5.7 (66.67cc)

- 241—’01-’03 (updated LS1), aluminum, center-bolt, 5.7 (66.67cc)

- 243 —’04-up (LS6/LS2), aluminum, center bolt, 5.7; also in some ’05-up trucks (64.45cc)

- 706/852/862—’99-up 4.8-5.3 truck heads (61.15cc)

- 035/317/873—’99-up LQ9 and LQ4 6.0 truck heads (71.06cc)

- 799—’05-up 4.8-5.3 truck heads; these are basically 243 Heads

LS Rectangular Port Heads

L92 heads (often referred to as LS3 heads) moved to a rectangular port and are some of the best LS heads ever made, far outflowing their cathedral port cousins. This port design is also found on some 6.0-liter truck engines (and on the Pontiac G8 6.0-liter mill) as well as Cadillac CTS-Vs and the LS9 in the Corvette ZR1. Due to an enlarged intake valve, these heads use an offset rocker on the intake side. The major difference in the various heads is the type of valve used. The LS3 821 heads had hollow-stem valves, as did the LSA supercharged engine with the 863 heads. Heads for the LS9 used titanium intake valves like the LS7. The main difference between an LSA and an LS9 head is the valves as well—the LSA heads used a stronger rotocast A356-T6 alloy.

- 373/873 LQ4 heads—71cc

- 716/821 LS3 heads—68cc

- 863 ZL1/CTSV LSA heads (thicker deck for boost)—68cc

- 823/5364/2716 L92 heads—68cc

LS7 Head Differences

LS7 heads (452 castings), like the L92 heads, employ rectangular ports (a bit wider and shorter compared to the L92/LS3 ports). The 12-degree design supports a straight-through airflow and utilizes 270cc intake ports. Also unique is the fact that the ports and combustion chambers are CNC-ported straight from the factory. These heads only use LS7 intake manifolds or an aftermarket equivalent. These were also known for using titanium intake valves and sodium-filled exhaust valves, something previously unheard of in a pushrod V-8. They easily support over 600 hp naturally aspirated and the huge valves necessitate 4.125-inch or larger bores.

LS Crankshaft Differences And What To Look For

For the most part, all LS cranks are of the same design and have 2.10-inch rod and 2.65-inch main journal sizes. They are all iron with the exception of LS9, LS7, and LSA cranks which are forged steel. LS7 cranks have a 4-inch stroke while all the rest have a 3.62-inch stroke (except 4.8-liter cranks which are 3.27-inch). LS7 and LS9 (dry-sump) cranks have a longer snout (about 1 inch) for their two-stage oil pumps, but can be used on wet-sump engines with the right parts and a modification or two. Another major difference between LS cranks is the reluctor wheel used for crank timing. Early ones will have a 24x wheel while later cranks will have a 58x wheel (shown above). The reluctor wheels can be changed by any qualified machine shop.

Are All LS Rods the Same?

Most LS rods are interchangeable and made from powdered metal. The exceptions would be LS9 and LS7 rods (6.067-inch) which are forged titanium (LS7/9 rods only work with LS7/9 pistons). The common length is 6.098 inches, except for 4.8-liter engines which use 6.275-inch rods. LS7 rods have a unique bearing size that requires a different bearing than other LS rods. The weak point of all LS rods would be the rod bolts, but this is especially true of pre-2000 engines. LS6 rod bolts (PN 11600158) would be an upgrade, and an even better option would be a set of ARP rod bolts. Remember that LS rods use a “cracked cap” design. That means each cap is an exact match to its rod, so never get them mixed up!

What Pistons Do LS Engines Use?

All LS engines, with the exception of the LS9, use hypereutectic (fancy term for cast) aluminum pistons. The biggest differences between the various pistons are the diameter, due to bore size changes, and those changes that affect compression ratio, such as a dish. Like cast pistons, they don’t like detonation and are good up to 550-600 hp, tops. Gen III pistons are held to the rod by a pressed-in (interference fit) pin, so a machine shop will need to take them apart and reassemble. Gen IV (and Gen III LQ9) used “full floating” pins held in by locking rings.

Comments (0)